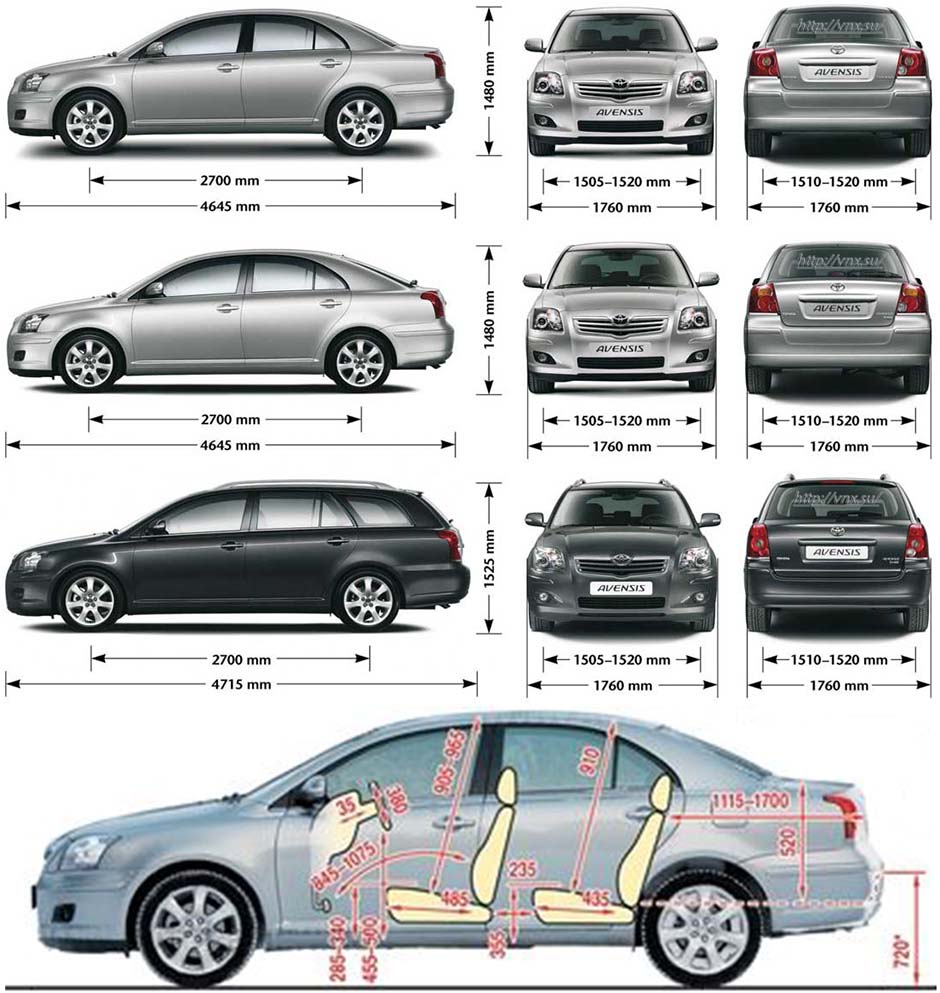

Кузов Toyota Avensis имеет следующие технические характеристики:

- Унифицированный кузов из стального листа с различными вариантами.

- Спереди имеются панель проема решетки радиатора, установленная на болтах, а также поперечина, изготовленные из пластика - окрашенные в цвет кузова транспортного средства.

- Крылья автомобиля прикреплены по месту болтами.

- Ветровое стекло, боковые и задние окна отполированы.

• Герметизация швов боковых панелей произведена после нанесения окраски. Это обеспечивает следующие преимущества:

- Герметизирующий материал не становится хрупким.

- Соответствующие работы по герметизации могут быть произведены без дополнительной окраски.

• Все детали кузова оцинкованы для защиты от коррозии (8-летняя гарантия от сквозной коррозии).

• Пассивная безопасность обеспечивается посредством:

- Зон запрограммированного смятия (рассчитанных мест сминания) в передних лонжеронах.

- Усиления между стойками А - обеспечивает поглощение боковых ударов и поддерживает панель приборов.

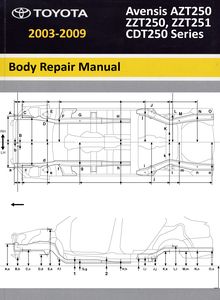

PRECAUTIONS FOR REPAIRING BODY STRUCTURE PANELS

1. HEAT REPAIR FOR BODY STRUCTURE PANELS Toyota prohibits the use of the heat repair method on body structure panels when repairing a vehicle damaged in a collision. Panels that have high strength and rigidity, as well as a long life span for the automobile body are being sought after. At Toyota, in order to fulfill these requirement, we use high tensile strength steel sheets and rust preventive steel sheets on the body. High tensile steel sheets are made with alloy additives and a special heat treatment in order to improve the strength. To prevent the occurrence of rust for a long period of time, the surface of the steel is coated with a zinc alloy. If a body structure parts are heat repaired with an acetylene torch or other heating source, the crystalline organization of the steel sheet will change and the strength of the steel sheet will be reduced. The ability of the body to resist rust is significantly lowered as well since the rust resistant zinc coating is destroyed by heat and the steel sheet surface is oxidized.

2. STRUCTURE PANEL KINKS A sharp deformation angle on the panel that cannot be returned to its original shape by pulling or hammering is called a kink. Since structure parts were designed to exhibit a 100% performance when they were in their original shape, if they are deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same performance as intended in the design. It is necessary to replace the part where the kink has occurred.

3. IMPACT BEAM REPAIR The impact beam and bracket are necessary and important parts in maintaining a survival space for passengers in a side collision. For impact beam, we use special high tensile strength steel. The high tensile strength steel maintains its special crystalline organization by heat treatment or alloy additives. Since these parts were designed to exhibit a 100% performance when they were in their original shape, if they are deformed in an accident, or if the deformed parts are repaired and reused, they become unable to exhibit the same performance as intended in the design. It is necessary to replace the door assembly when impact beam or bracket is damaged.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||